Unibar ADI is primarily used for applications in this industry sector. They present substantial advantages over other material types.

Reliability is one of the key factors when specifying Unibar ADI. The cost of downtime due to failure or late delivered parts can run into 000's per hour. Unibar ADI guarantees reliable, on-time deliveries backed by a technical expertise second to none. Manufacturers utilise the superior qualities of Unibar ADI to achieve significantly improved machining times which leads to overall cost savings with improved mechanical characteristics.

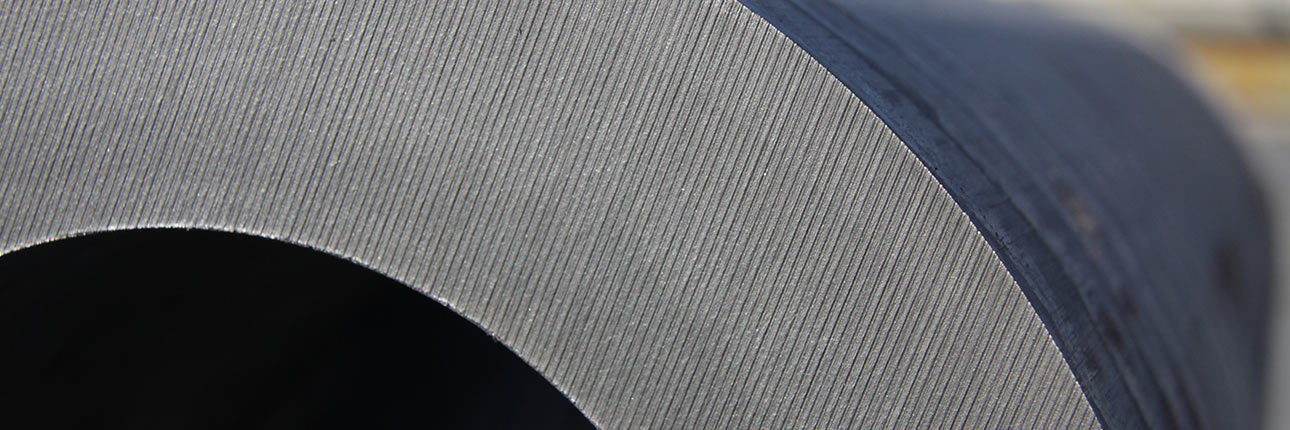

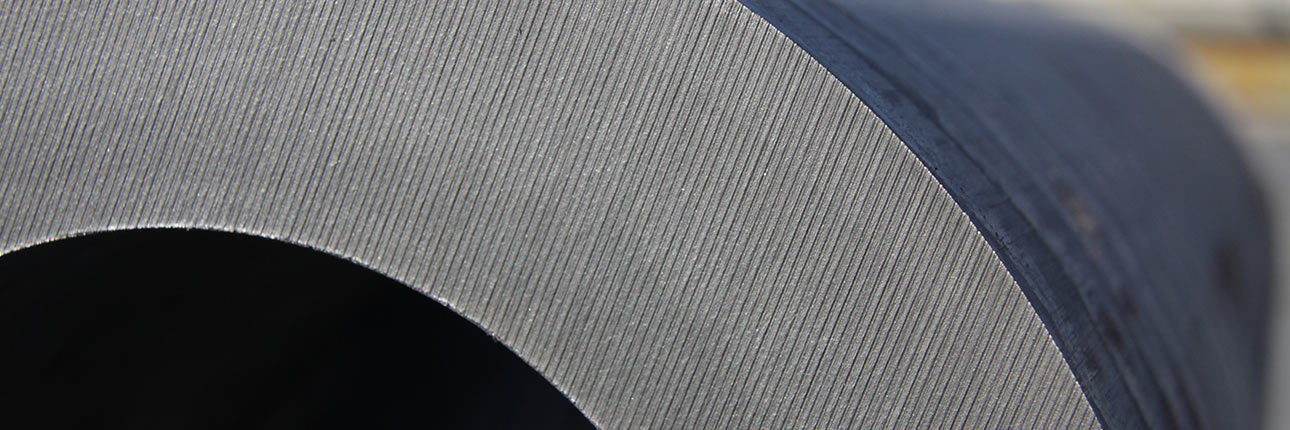

The machinability of all the Unibar grades of iron is such that complex forms, bores and keyways can be machined up to 50% faster than in tool steel and forged steel. In cold metal forming applications, the presence of graphite in the microstructure has improved productivity on materials that are prone to producing dust and swarf during the rolling operation such as galvanised coated steel. Additionally Unibar ADI is used in cold aluminium rolling where the aluminium is prone to stick to tool steel.