Grade Colour Code: Yellow

SG/Nodular Iron

Comparative Specification:

Unibar 400-15 offers superior machinability and surface finish combined with good fatigue strength, electrical conductivity and magnetic permeability. Noise and vibration damping are good in this grade.

Standard cut length of our cast iron products is 3080mm, other lengths available on request.

| Round | Square | Rectangle | Special Profiles |

|---|---|---|---|

| 25mm – 700mm | 25mm x 25mm – 550mm x 550mm | Up to 780mm x 550mm | Sizes and profiles to customer design available on request |

| Material Section mm | Tensile Strength N/mm² | 0.2% Proof Stress | Elongation % | Hardness (BHN) | Matrix |

|---|---|---|---|---|---|

| 20 < D ≤ 60 | 400 | 250 | 15 | 120 - 180 | Ferritic |

| 60 < D ≤ 120 | 390 | 250 | 14 | ||

| 120 < D ≤ 400 | 370 | 240 | 11 | ||

| 400 < D ≤ 700 | 370 | 240 | 11 |

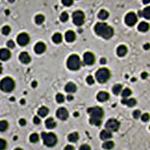

Contains type V & VI nodular (spheroidal) graphite in accordance with ISO 945. The rim is predominantly ferritic (>90%). The core matrix is essentially ferritic with ≤10% pearlite. Chill carbides will be less than 5%, well dispersed.

Unibar 400-15 is not recommended for heat treatment, the higher pearlitic Unibar 600-3 and Unibar 700-2 are more suitable.

Both, our foundries and our local distribution centres offer various services to deliver pre-machined products to our customers. Pre-machined Unibar material will save valuable production time, improve the cost effectiveness and eliminate waste in your own production, allowing you to focus on the key design elements of your products.

Cutting to specified length in quantities as little as one piece to large volumes, prepared to meet the requirement of your automatic machining systems.

Turning of round bars to required size to meet specific requirements and to minimise the machining operations of our customers. Unibar turned therefore comes with a standard tolerance of +1mm, although after consultation we can offer alternatives to suit all of our customers‘ requirements.

Single and duplex machines offer milling of square and rectangular bars to specified dimensions and agreed tolerances. We can offer our customers milling on either four or six faces for further processing.

In the case of machined Unibar with diameters of less than 110mm as an alternative to Unibar turned we can offer Unibar peeled by peeling off the oxidised surface layer of the cast bar. As these are smaller dimensions and involve a different machining process, the tolerances offered are more precise, for example h11.

Longitudinal boring as deep as 1000mm is possible by using single head boring and trepanning machines. Unibar tubes can be supplied with the exterior surface as-cast or machined. These two variants can be complemented by a wide selection of internal measurements, which can range from 30mm to 500mm.

| Round (As-Cast Diameter mm) | Ovality Allowances mm | Max. Swell Allowances mm |

|---|---|---|

| 20 < (D OR B) ≤ 50 | - | 5 |

| 50 < (D OR B) ≤ 100 | 2 | 7 |

| 100 < (D OR B) ≤ 200 | 3 | 10 |

| 200 < (D OR B) ≤ 300 | 4 | 12 |

| 300 < (D OR B) ≤ 400 | 5 | 15 |

| > 400 | By agreement | By agreement |

| Section (D Diameter, B Width) | Min. Machining Allowance mm (per side) | |

|---|---|---|

| Round | Square/Rectangle | |

| 20 < (D OR B) ≤ 50 | 3 | 3.5 |

| 50 < (D OR B) ≤ 100 | 4 | 4.5 |

| 100 < (D OR B) ≤ 200 | 5 | 5.5 |

| 200 < (D OR B) ≤ 300 | 7 | 7.5 |

| 300 < (D OR B) ≤ 400 | 8 | 8.5 |

| 400 < (D OR B) ≤ 500 | 10 | 10.5 |

| 500 < (D OR B) ≤ 650 | 12 | 12.5 |

For rectangular bars the width is the longer dimension of the cross section. Machining allowances of our continuously cast iron bars can be adjusted to meet customer requirements, subject to discussion, prior agreement and special order. For further information please contact our nearest distribution centre.

Our nodular iron grade Unibar 400-15 is suitable for various applications due to its microstructure and the mechanical properties. It is used for applications within the hydraulic and pneumatic industry, the automotive industry, the machinery and machine tool section, for pumps and compressors, within the oil and gas industry as well as for the steel machinery.

Unibar 400-15 is often used as a favourable alternative for other materials such as steel, aluminium or sand casting.

Do you need any further information about our continuously cast iron products? You will find the appropriate data sheets as well as our technical manual in our download section.

To find out whether Unibar 400-15 is available in your required size, please have a look at our online stock list. Register and keep track of the currently available quantities.